International: english

International: englishInternational: english International: englishAustralia: english

International: englishAustralia: english Australia: englishAustria: deutsch

Australia: englishAustria: deutsch Austria: deutschCanada: english

Austria: deutschCanada: english Canada: englishCzechia: český

Canada: englishCzechia: český Czechia: českýDenmark: dansk

Czechia: českýDenmark: dansk Denmark: danskFinland: suomi

Denmark: danskFinland: suomi Finland: suomiFrance: français

Finland: suomiFrance: français France: françaisGermany: deutsch

France: françaisGermany: deutsch Germany: deutschHungary: magyar

Germany: deutschHungary: magyar Hungary: magyarItaly: italiano

Hungary: magyarItaly: italiano Italy: italianoNetherlands: nederlands

Italy: italianoNetherlands: nederlands Netherlands: nederlandsNorge: norsk

Netherlands: nederlandsNorge: norsk Norge: norskPoland: polski

Norge: norskPoland: polski Poland: polskiRomania: românesc

Poland: polskiRomania: românesc Romania: românescSlovakia: slovenčina

Romania: românescSlovakia: slovenčina Slovakia: slovenčinaSpain: español

Slovakia: slovenčinaSpain: español Spain: españolSweden: svenska

Spain: españolSweden: svenska Sweden: svenskaSwitzerland: deutschUAE: english

Sweden: svenskaSwitzerland: deutschUAE: english UAE: englishUnited Kingdom: english

UAE: englishUnited Kingdom: english United Kingdom: englishUSA: english

United Kingdom: englishUSA: english USA: english

USA: english

International: english

International: english Australia: english

Australia: english Austria: deutsch

Austria: deutsch Canada: english

Canada: english Czechia: český

Czechia: český Denmark: dansk

Denmark: dansk Finland: suomi

Finland: suomi France: français

France: français Germany: deutsch

Germany: deutsch Hungary: magyar

Hungary: magyar Italy: italiano

Italy: italiano Netherlands: nederlands

Netherlands: nederlands Norge: norsk

Norge: norsk Poland: polski

Poland: polski Romania: românesc

Romania: românesc Slovakia: slovenčina

Slovakia: slovenčina Spain: español

Spain: español Sweden: svenska

Sweden: svenska UAE: english

UAE: english United Kingdom: english

United Kingdom: english USA: english

USA: englishHow to: Subsequently produced load-free zone under a roadway

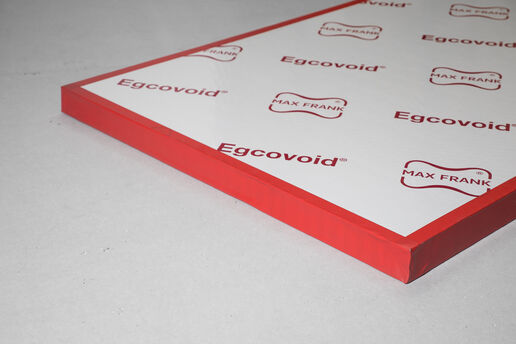

Egcovoid® void former in the installation, © www.maxfrank.com

With the Egcovoid® former, you can reach a planned load-handling after the concreting.

To protect subterranean concrete structures against unintended loads, a flatly load-free layer must be created. This prevents unintended load, by deflections due to dynamic traffic loads (heavy vehicles, trucks, etc.). With the Egcovoid® former, you can reach a planned load-handling after the concreting.

How to:

- The Egcovoid® panels are laid over a sandbed or similar underground. The choice of the plate thickness (35 mm or 50 mm) depends on the calculated deflection of the decoupled roadway plate.

- The individual plates are connected securely to each other with a hose system (MAX FRANK accessories) at the prefabricated valve points. The sufficiently long tube end is guided upwards over the bottom plate.

- A PE film is laid over the Egcovoid® panels as additional moisture protection, a clean concrete layer is applied as mechanical protection to the PE film.

- After the base plate hardens, the Egcovoid® former are watered via the mounted hose system. Due to the water applied, the Egcovoid® panels create a load-free layer and an independent bearing bottom plate.

We recommend